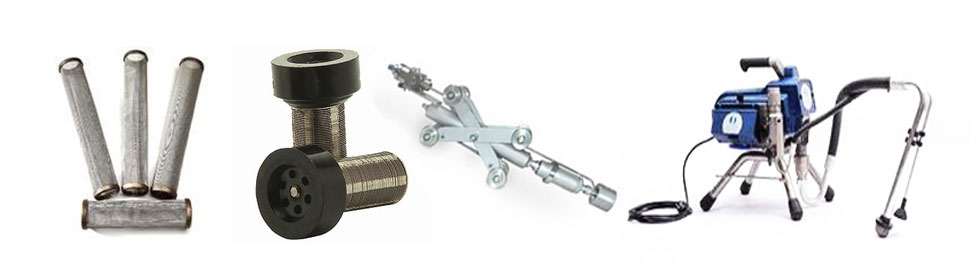

⇓ Spray Painting Equipment

We are a leading Manufacturer & Exporter of Spray Painting Equipment such as Airless Spray Painting Pump, Airless Spray Painting Equipment, Airless Paint Sprayer, Contractors Heavy Duty Airless Spray Painting Equipments and Airless Spray Painting Machine from India.

⇓ Spray Painting Equipment

Item Code: Model-S301

Item Code: Model-S301

We are instrumental in offering a quality range of Spray Painting Equipment - Model S301. These are fitted with a reliable mechanical air motor that offers higher efficiency and minimum maintenance. Furthermore, these equipment are provided with high performance airless sprayers, which is specially designed for zinc rich primers zinc silicate. Some of the salient features are:

Airless Sprayers

- More durable with longer Life packing design.

- Reliable Mechanical air motor provides higher efficiency & minim maintenance More durable with longer Life packing

High performance Airless Sprayers specially design for zinc rich primers zinc silicate epoxy paint & primers, Polyurethane coatings Enamels paints & primers Low solvent coatings lacquers.

Applications

|

Typical Fluids Handled

|

⇓ Airless Spray Painting Pump

Item Code: Model-S601

Item Code: Model-S601

We offer our clients a wide range of Spray Machine These are provided with a rust proof stainless steel coating and high performing hydraulic circuits. Moreover, the equipment is durable and requires overall low maintenance cost. Our range of Airless Spray painting Equipment -Model S601 is used for the purpose of fire retarding coating and is widely used in offshore industries. Some of the additional features and application areas are mentioned below:

Features:

- Designed for handling variety of coatings with powerful spray & with stands the toughest working conditions.

- lRust proof Stainless Steel hydraulic circuits.

- lPositive displacement, piston pump design Provides Uniform, easily controlled delivery

- lHigh Flow rate Light & easy to handle, Long life high quality precision parts.

- lHigher pressure ratio for higher flows, longer hose lengths and better atomisation.

- lMore durable with longer life. Mechanicals air motor provides higher efficiency even with lower air inlet pressure.

- lImproved serviceability with fewer parts.

- lProperly designed filters reduces pressure drop & improves flow.

Applications

|

Typical Fluids Handled

|

⇓ Airless Paint Sprayer

Item Code: Model-S451

Item Code: Model-S451

We offer a wide range of Spray Painting Machinet- Model S451. These have high flow rate, are light and are easy to handle with precision engineered parts & components. Further, our range of Spray Painting Equipment - Model S451 is used for internal external pipe coating, structural coating and fire retarding coating. Some of the equipments’ additional features and application areas are:

Airless Sprayers

- More durable with longer Life packing design.

- Reliable Mechanical air motor provides higher efficiency & minim maintenance More durable with longer Life packing

High performance Airless Sprayers specially design for zinc rich primers zinc silicate epoxy paint & primers, Polyurethane coatings Enamels paints & primers Low solvent coatings lacquers.

Applications

|

Typical Fluids Handled

|

⇓ Contractors Heavy Duty Airless Spray Painting Equipments

Features of Contractors Heavy Duty Airless Spray Painting Equipments:

Features of Contractors Heavy Duty Airless Spray Painting Equipments:

- Designed for handling variety of coatings with powerful spray & with stands the toughest working conditions.

- More durable with longer life packing designs.

- Compact and maintainance free hydraulic part.

- High flow rate, light and easy to handle.

- Easily detachable suction port reduces cleaning and maintainance time.

Typical Fluids Handled

- Epoxy primers

- Higher volume solid & high viscosity coatings Solvent less coatings

- Epoxy mastics

- Waterproof coatings

- Fireproof coatings

- Polyurethane top coats

- Jams and Jelly transfer.

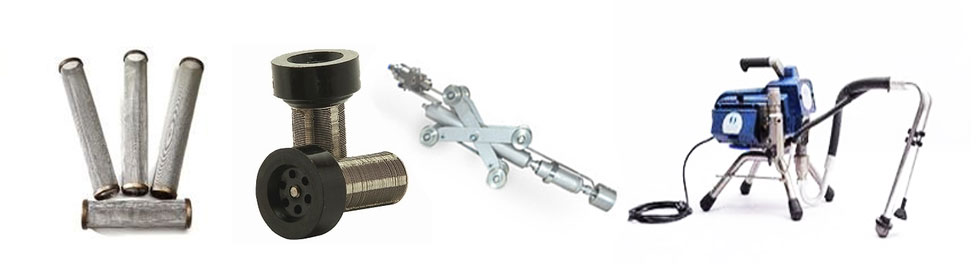

⇓ Airless Spray Painting Machine

Medium Duty Airless Spray Painting Equipments specially design for Enamels paints and primers, Epoxy paints and primers and Polyruthane coatings Low viscous coatings and lacquers.

Medium Duty Airless Spray Painting Equipments specially design for Enamels paints and primers, Epoxy paints and primers and Polyruthane coatings Low viscous coatings and lacquers.

Suitable for Airless air Assisted spray painting.

Positive displacement piston pump provides uniform and easily controlled finishing.